Passivation

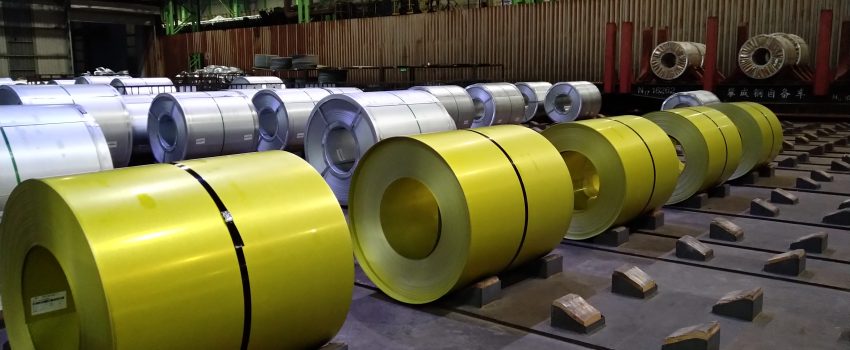

Ecosil’s passivation products are one-component waterborne solutions for galvanized steel sheet

Galvanized Steel Passivation Products

The formulation is chrome free use environmentally-friendly organo-silane compounds. These products are designed to provide excellent corrosion protection for zinc-coated steel sheets. The suited substrates include:

- Hot-dip galvanized steel (GI),

- Electro-galvanized steel (EG),

- Galvalum (GL),

- Galvaneal

- Zinc-aluminum-magnesium (Zn-Al-Mg) coated steel.

Our passivation products have been used to produce home appliances, construction and building materials and automobile parts. These products have also been designed to provide specific properties such as anti-fingerprint marking, self-lubrication and decorative color for architectural uses.

Passivation Product Descriptions

Ecosil solves the problem of metal corrosion with innovative surface treatment products with high corrosion resistance that are non-toxic, and cost effective. We bring together teams of technology innovators and researchers, funders, and manufactures to commercialize innovative pretreatment technologies.

On galvanized steel (GI):

- XCF series: Cr-free passivation

- XAF series: Cr-free anti-finger print coat

- XSL series: Cr-free self lubrication passivation product

- XTC series: Cost effective trivalent chromium passivation

On 55% Al-Zn coated steel (GL):

On Zn-Al-Mg coated steel :

- XAF series: Cr-free anti-finger print coat

- XTC series: Cost effective trivalent chromium passivation

Self-Lubricating surface treatment (Multi-Functional Passivation Treatment)

Ecosil’s multi-functional surface passivation treatment (MPT) has been developed to provide galvanized steels with outstanding corrosion resistance, and surface lubricity for downstream metal forming applications.

Advantages of this product are:

- Elimination of the use of forming lubricants

- No post lubrication or rinsing of the film is required

- High corrosion resistance

- Can be colored

- Solvent free and environmentally friendly

- Applicable to a variety of metals

The MPT can applied onto galvanized steel sheets by rolling or spraying to form a water resistant thin film (~1 μm) to prevent metal corrosion during transit or storage. Non-toxic corrosion inhibitors in the film provide a "self-repairing" characteristic, and polymeric additives provide excellent lubrication properties. The MPT technology provides a significant cost reduction by eliminating the need for metal forming oils and degreasing chemicals which also lowers waste treatment costs.

Ecosil’s MPT passivation product was nominated for a 2017 Corrosion Innovation of the year award by the National Association of Corrosion Engineers (NACE) due to the multiple functions of corrosion resistance and replacement of forming oils and avoidance of rinsing to remove the forming oil thereby significantly reducing cost and environmental impact. Read Article.

For product information and to purchase products:

In North Americal – Ecosil Technologies 513-858-2365

In China – Xingyu Ecosil - www.xingyu-ecosil.com